- Home

- Products

- AGI Glassplant

- Reaction

- Benchtop Reactor

Benchtop Reactor

AGI Benchtop Reactor is built for top performance at lab-scale and has been engineered to provide a great user experience.

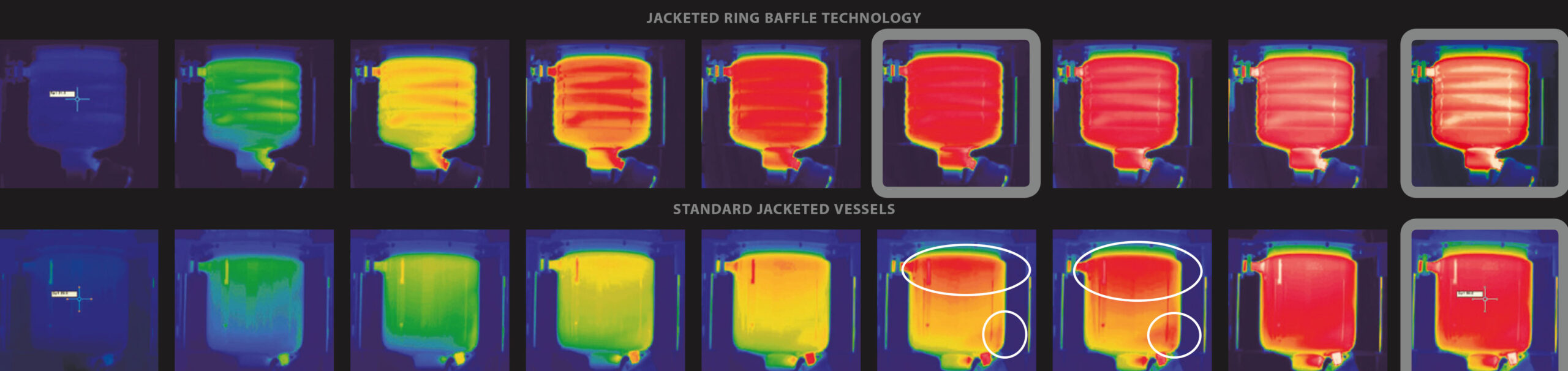

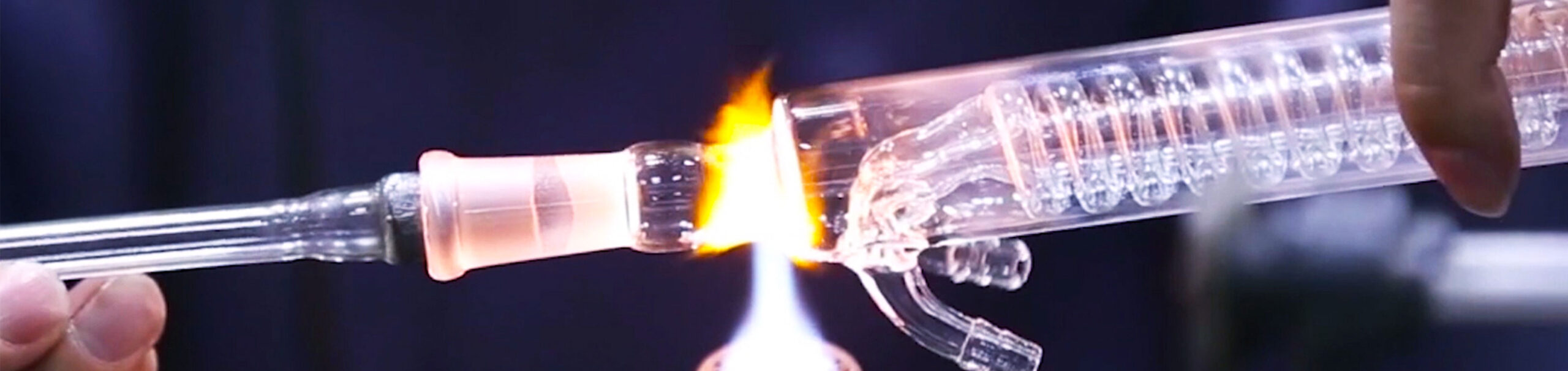

The superior reaction performance is delivered via the unique Ring Baffle located in the reactors’ thermal jacket. This provides a quick and efficient thermal exchange between the process and thermal source.

Other notable performance factors are a wide process temperature range, high thermal shock resistance and vessel geometry similar to industrial vessels.

Our Benchtop Reactor is a compact system with interchangeable vessels (300 ml to 5 L) and is suitable for placing in a fume hood. Various vessel options and accessories allow you to choose exactly what you need for your process.

Premium options are also available to simplify workflow, provide an enhanced user experience, and save valuable time.

- Fast achievement of reaction set-point temperature.

- Reduced energy consumption.

- Interchangeable vessels (300 ml to 5 L).

Why should you choose AGI Benchtop Reactor ?

We integrated our knowledge into a system that offers the following advantages :

Wide process temperature range : -90 °C to +230 °C

Thermal jacket with Ring Baffle for excellent temperature control

High ΔT - Thermal shock resistance 110°C (Double wall), 60°C (Triple wall)

Removable flush valve for easy cleaning

One support structure for vessels from 300 mL to 5 L

Interchangeable vessels and accessories

For an in-depth explanation of why AGI reaction systems are best for you, click here.

- Reaction – vacuum to atmospheric pressure

- Temperature monitoring

- Regulation of temperature

- Reflux condensation

- Agitation

- Dosing liquids

- Additional functionality - see our customization section

| Vessel capacity | 300 mL, 500 mL, 1 L, 2 L, 3 L and 5 L |

| Vessel type | Double wall or triple wall. Ring Baffles available for both types |

| Operating pressure | Full vacuum to atmospheric pressure |

| Operating jacket pressure | Up to +0.5 barG (0.05 MPa) |

| Operating temperature | -90 °C to +230 °C |

| ΔT – Thermal shock resistance | 110 °C (double wall), 60 °C (triple wall) |

We are happy to discuss the design of custom features for the AGI Benchtop Reactor in order to meet your specific process need. Our technical knowledge and skill in manufacturing scientific glassware means that we can implement almost any requirement and ensure that the custom reactor features are both reliable and user friendly.

AGI Benchtop Reactor Customization Examples

- PTFE reaction vessel cover

- Modification of port orientation in glass cover

- Modification of port sizes to accommodate various accessories

- Special glass cover accessories

- Modification of reaction system to withstand operating pressure up to 0.5 bar G

- Up to 300 °C usage

- Addition of distillation line

- Quartz version

- Glass internal baffles

- Full jacket design

- EU and American standards of ports

- Joint variations including TS, Screw, GL