From feasibility testing to small scale production

With laboratory units, reliable conclusions about the feasibility of a distillation process can be made by using only small product amounts. The set-up and design of our lab units is based on many years of experience gained in our own test center. The key components in lab scale systems are fabricated in borosilicate glass. This enables observation of product properties like foaming, fouling and film distribution on the heated shell during distillation.

Why laboratory units ?

Feasibility testing for new distillation tasks and products

Feasibility testing for new distillation tasks and products

Feasibility testing for new distillation tasks and products

Required raw material quantities about 1 – 3 kg

Determination of process parameters

MOC of evaporator: Borosilicate glass

features

- Capacity: 20 g/h up to 6 kg/h

- Operating pressure :

- min. 0,1 mbara for Wiped Film Evaporator

- min. 0,001 mbara for Short Path Evaporator

- Heating temperature: max. 350 °C

- Evaporator size: 0,01 m² - 0,40 m²

- Material of construction: borosilicate glass, stainless steel, special synthetic materials

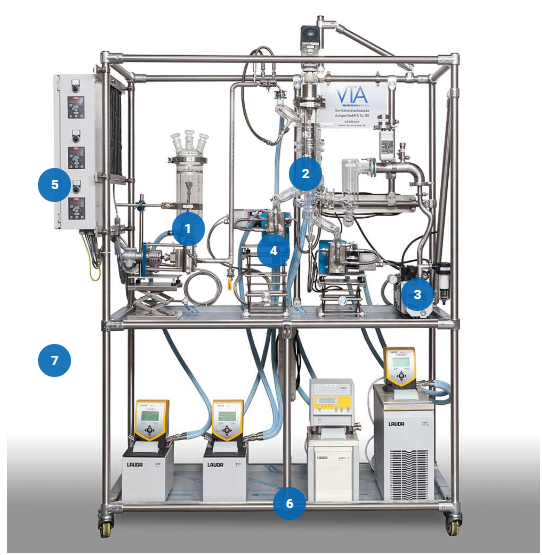

Standard Set-up and Options

1. Feed

- Gear pump

- Membrane pump

- Dosing vessel

2. Evaporator

- Short Path Evaporator

- Wiped Film Evaporator

- Horizontal Thin Film Evapoator

- Wiped Film + Rectification column

3. Vacuum system

- Rotary vane pump

- Oil diffusion pump

- Membrane vacuum pump

4. Discharge

- Gear pumps

- Glass flasks

- Triple split distributors

- Intermediate buffer vessels

5. Electrical equipment

- Manual operation(standard)

- PLC control and process visualization

6. Skid

- Moveable skid

- Installation on bench (e.g. fume hood)

7. Configurations

- Single stage

- Multi stage

- Wiped Film Evaporator with column

- Tailor made systems

The design of our distillation systems is based on our customers´ requirements and product properties.

The following options can be considered for our tailor-made systems :

- Evaporator types : Wiped Film, Short Path, Horizontal Thin Film

- Different wiper systems

- Fractional distillation systems

- Continuous feeding and discharge options

- Trace heating and tempering

- Material selection (product wetted)

- PLC and visualization option

- Multi-stage and combined distillation systems