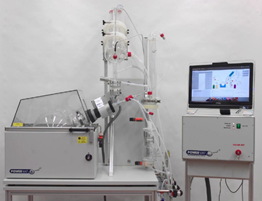

Rotary evaporator POWERVAP®

POWERVAP® is a patented, fully automated pendulum system rotary evaporator.

The performance of the POWERVAP® is approx. factor 5, compared with a manual rotary evaporator system, which has the same size of rotating flask.

POWERVAP® Applications :

- Excellent suitable for recovery of solvents.

- Problem-free distillation of high boiling solvents.

- Distillation of large amounts of solvent.

- Concentration of extracts.

- Concentration of fractions coming from HPLC.

- We would be glad to develop with you customer specified solutions. With our patented line of fully automated rotary evaporators, we can offer you completely novel and greatly enhanced possibilities.

Technical Details of the POWERVAP® :

- Automatic filling and emptying of the rotating flask (patented).

- Automatic emptying of the distillate chamber.

- Generation of a desired product concentration.

- Automatic removal of liquid or viscous concentrates.

- Handling of foam by means of parametric pulse dosing system (option/patented).

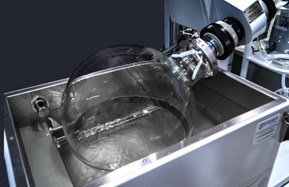

Floating rotating flask, which contents is controlled by means of an inclinometer

Floating rotating flask, which contents is controlled by means of an inclinometer- The floating rotating flask reduces mechanical stresses, to achieve by constant tightness, a powerful distillation, even under permanent operation (see pendulum system).

- Hydraulic damping system for the rotating flask with drive system (patented), to increase the performance, when drying powders.

- Surface treated glass flanges for maximal vacuum stability.

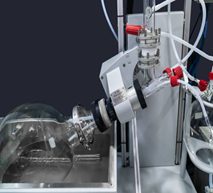

High performance sealing system

High performance sealing system

– PTFE/glass

– Service life approx. 20,000 hours of operation

– Final vacuum better than 0.1 hPa (when empty)

– 3 years warranty- Sealing system STACONSEAL, patented (option)

– Final vacuum better than 0.01 hPa (when empty) - By means of the novel sealing system, a very good solvent recovery rate will be achieved

- Vapor temperature alarm to shut off the water bath automatically

- Implosion protection hood for the rotating flask, made of transparent polycarbonate

- Hexagonal implosion protection system for the condenser, made of transparent polycarbonate.

- Full system surveillance by software-based error handling.

- Precise control of the distillation process. Temperature, vacuum and other process parameters are also controlled,

to handle foaming products - Computer controlled reflux: Therefore, facility can wait in standby-mode for new product. As a result, the system does not have to be restarted time-consuming.

- Unattended, safe and consistent operation

- For further information’s belonging to the control of the POWERVAP® series, please have a look at the page user interface & process optimization