- Home

- Products

- AGI Glassplant

- Reaction

- Pilot Plant Reactor Plus

Pilot Plant Reactor Plus

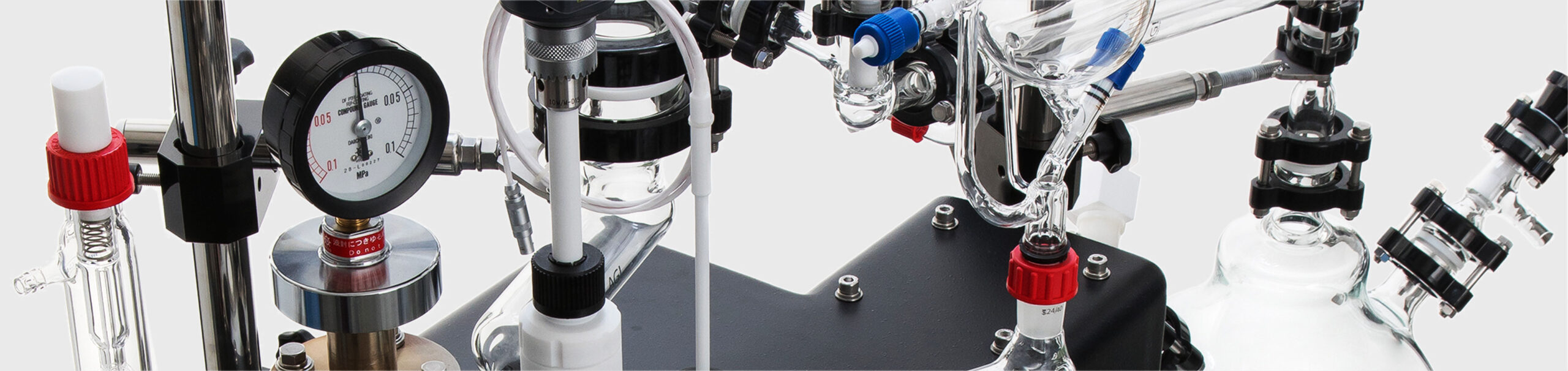

AGI Pilot Plant Reactor is designed for demanding applications, such as process development, kilo and pilot scale production. Performance, functionality, and ease of use are of the highest standard in this reactor. Ring Baffle technology, vessel geometry, and optimised wall thickness ensure high performance.

Exceptional usability of AGI Pilot Plant Reactor is provided via the flexible stand. By enabling quick and easy displacement of the vessel, it allows you to spend more time focusing on your process and less time setting it up. The system offers outstanding value and is available in 10, 20 and 30 L vessel capacities.

- High performance via Ring Baffle technology

- Wide range of custom options

- Simple and efficient handling

Why should you choose AGI Pilot Plant Reactor PLUS ?

AGI Pilot Plant Reactor is designed by experts to provide users with excellent performance and functionality. We have extensive experience in scientific glass fabrication and in providing solutions for a wide variety of chemical processing industries.

We integrated our knowledge into a system for batch production applications that offers the following advantages :

Functional stand for quick vessel access, impeller change and cleaning

Various lid accessories for process development

Easy to set up - more time for reaction process

Wide process temperature range; -90 °C to +230 °C

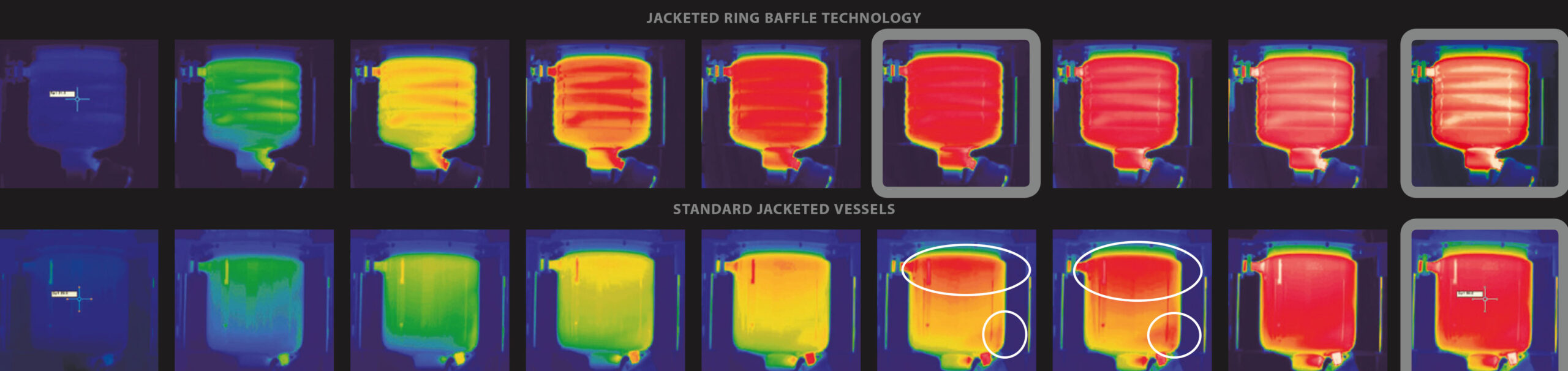

Thermal jacket with Ring Baffle for excellent temperature control

Full jacket vessel design for maximum performance

High ΔT - Thermal shock resistance 110°C (Double wall), 60°C (Triple wall)

Removable flush valve for easy cleaning

Sturdy stand with castors for mobility

For an in-depth explanation of why AGI reaction systems are best for you, click here.

- Reaction - vacuum to atmospheric pressure

- Temperature monitoring - via Pt100 thermal probe

- Temperature regulation - via thermal jacket

- Reflux condensation and distillation

- In - stand distillate cooling and collection

- Pressure monitoring and relief

- Inert atmospheric reactions

- Easy vessel access for impeller change

- Debris free agitation via AGI stirrer seal

- Dosing of solids and liquids

| Vessel capacity | 10 L, 20 L and 30 L |

| Vessel type | Double wall or triple wall*. Ring Baffles available for both types |

| Operating pressure | Full vacuum to atmospheric pressure |

| Operating jacket pressure | Up to +0.5 barG (0.05 MPa) |

| Operating temperature | -90 °C to +230 °C |

| ΔT – Thermal shock resistance | 110 °C (double wall), 60 °C (triple wall) |