Features

Explore the integrated features that let you perform your crystallisation process in a smart, swift, and safe manner

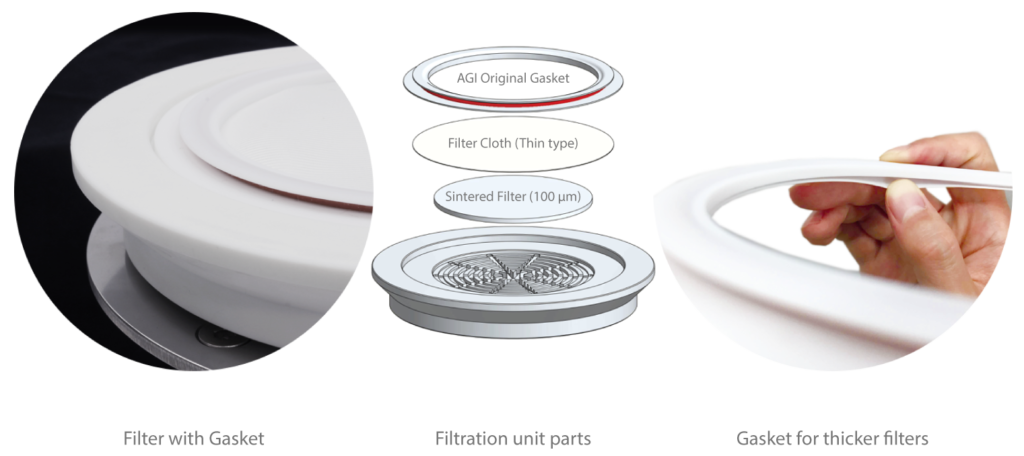

The filtration part is composed of a PTFE plate, a sintered filter to support your choice of filter membrane/cloth, and a gasket for holding it in place. The connection between the filter and glass vessel is secured by a quick release clamp, and the filter is supported by a lab jack when it is detached.

- Easily removable filter

- Safe handling of filtered material upon opening

Our filtration part is meticulously designed to perform washing and filtration effectively. The gasket with O-ring forms a perfect seal between the glass and the PTFE plate. For thicker filter cloth choices of up to 1 mm thickness, a special gasket is provided.

- No leaks or bypass around the filter membrane

Note : Since the pore size of filter membranes are variable, they are not included in the standard package.

Vessels can be rotated 360° in the stand using the vessel swing/rotation mechanism. This is a useful feature, especially if the end product volume is large and the filter can’t be opened without spilling. The lid can be removed and the vessel can be pushed out, rotated, and secured at any desired angle.

- Safe and easy recovery of the end product.

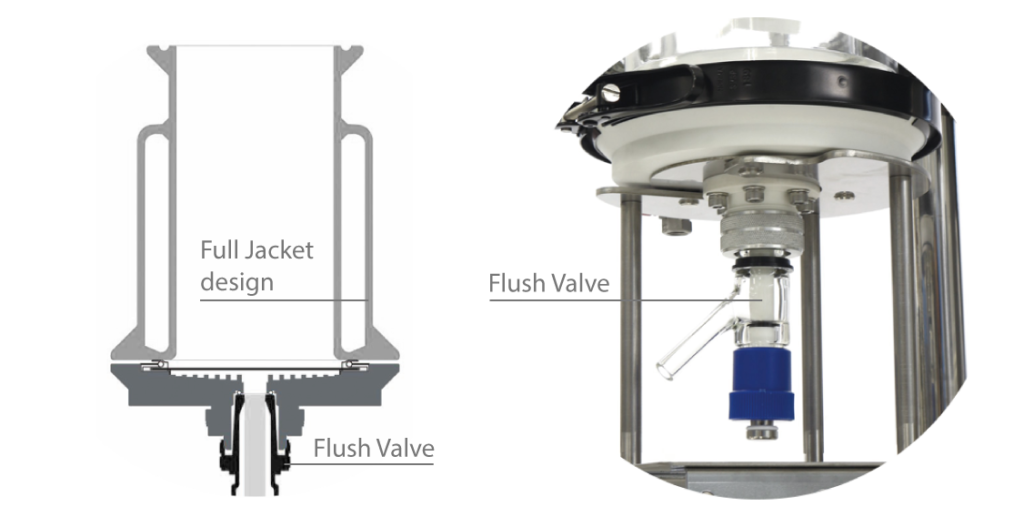

A full jacket design means that the thermal jacket fully covers the process vessel, which offers maximised thermal transfer to the process. The filter and flush valve are designed to provide very minimal dead space.

- High performing vessel

- Filter with low dead volume

The thermal jacket is connected to the thermostat tubings via quick-release couplings. At the end of the process, the tubings can be quickly removed and the vessel can be rotated for easy product collection. The couplings also have pressure safety valves that protect the glass vessel in case of over-pressure in the thermal jacket.

- Mess-free work space

- Convenience for product collection

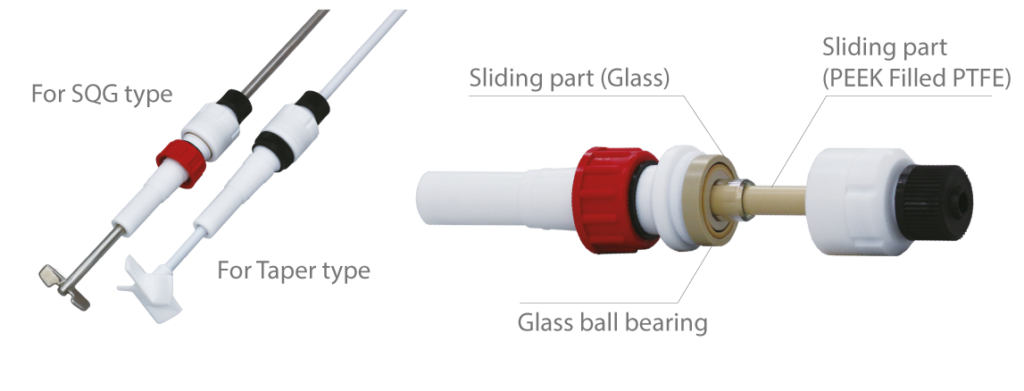

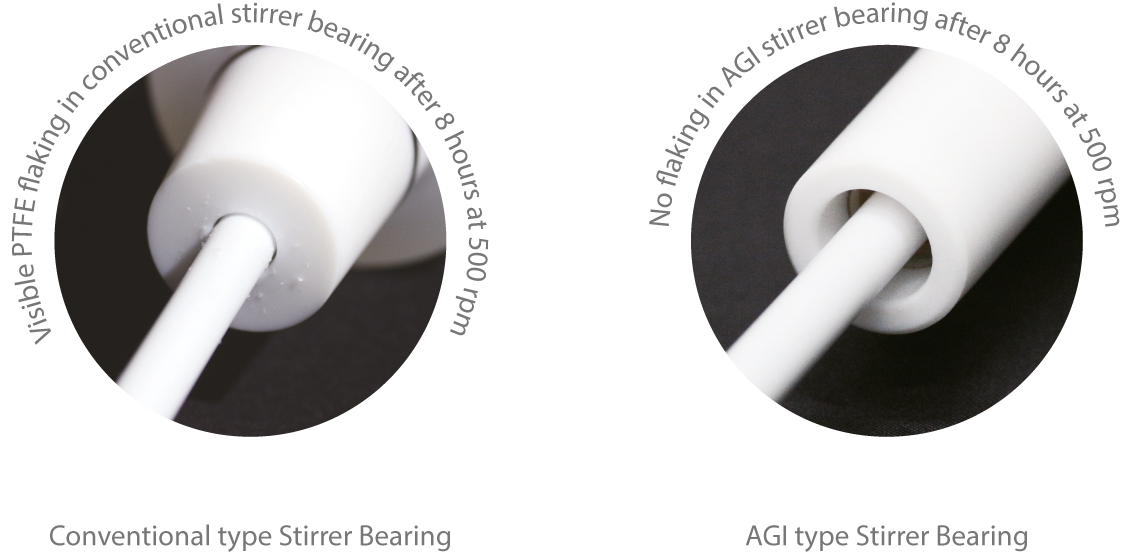

Newly designed AGI stirrer bearings have an extended configuration with glass and PEEK sliding parts.

Stable stirring

Debris-free stirring

Our testing showed that the AGI stirrer bearing has reduced PTFE flaking (from stirrer shaft) with prolonged operation compared to conventional bearings available in the market.

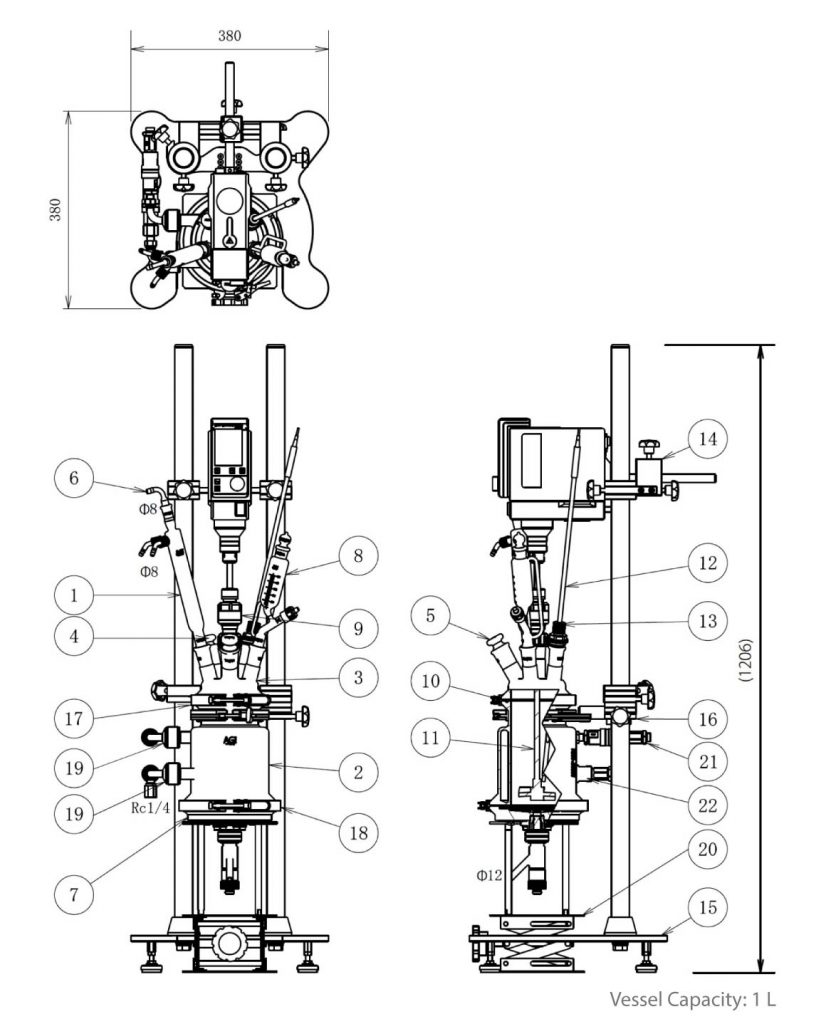

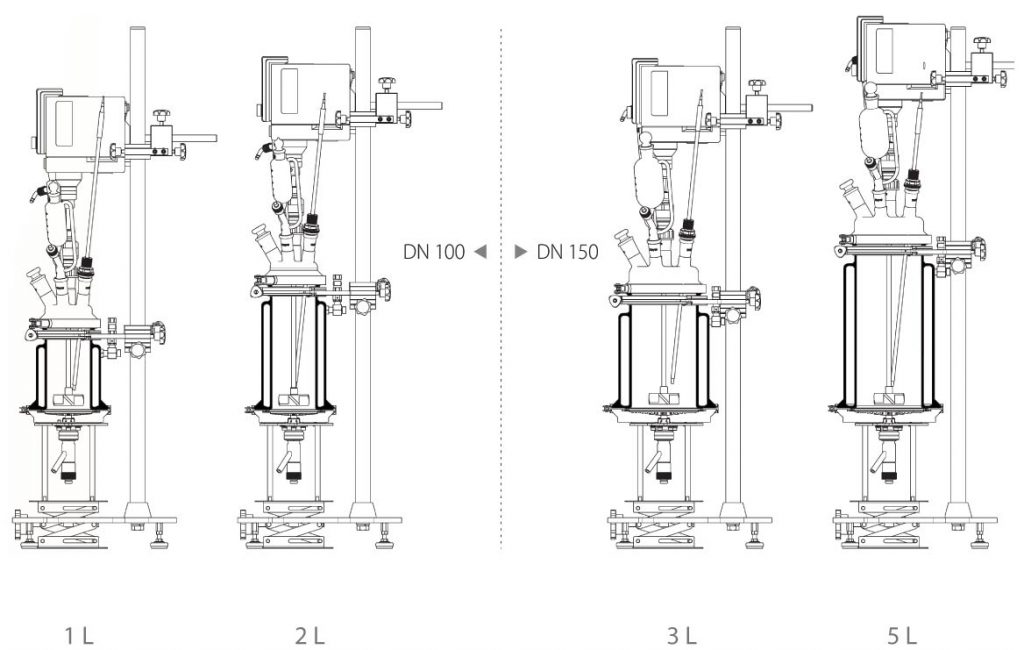

A single support structure can be used for mounting vessels from 1 L to 5 L, making it very easy to scale-up or scale-down.

*DN 100 vessels 1 L and 2 L require DN 100 clamp

*DN 150 vessel 3 L and 5 L require DN 150 clamp

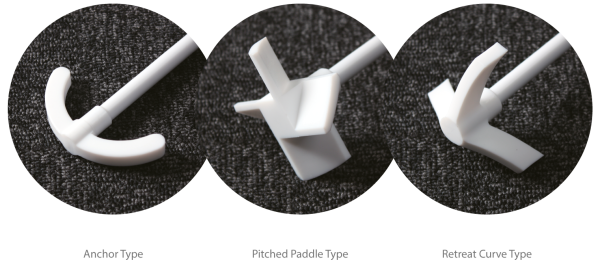

Mass flow pattern is an important factor to consider when you want to achieve a perfect chemical reaction process. We offer three types of impellers with axial or tangential flows. AGI impellers are made of SS rods encapsulated in PTFE for excellent chemical resistance and mechanical strength. If your application requires a special flow, see our advanced impeller options. If you find these are not sufficient, please contact us and we can help you to find a solution that suits your specific process.

- Dimroth Condenser, TS 24/40, TS 15/25

- Full Jacket Glass Body, DN 100 (1 L, 2 L) / DN 150 (3 L, 5 L)

- Glass Cover, DN 100 (1 L, 2 L) / DN 150 (3 L, 5 L)

Ports (SQG 29/42 x1, TS 24/40 x4, TS 29/42 x1) - Stopper for Additional Hole, TS 24/40

- Stopper for Hand Hole, TS 29/42

- Vent Adapter, TS 15/25

- Filtration Part, PTFE, DN 150 (1 L, 2 L) / DN 200 (3 L, 5 L)

- Dropping Funnel with Stopper, Graduated, TS 24/40

- PTFE Stirrer Guide, Glass Ball Bearing, SQG 29/42,

Shaft OD: 10 mm - O-ring, FKM

- PTFE Stirrer Shaft, Shaft OD: 10 mm

- Temperature Sensor Probe, OD: 8 mm, L: 660 mm

- Temperature Probe Holder, PTFE, TS 24/40, Probe OD: 8mm

- Motor Support

- Support Structure

- Tilting Clamp

- Quick Release Clamp, DN 100 (1 L, 2 L) / DN 150 (3 L, 5 L)

- Quick release clamp for bottom, DN 150 (1 L, 2 L) / DN 200 (3 L , 5 L)

- Metal Adapter for HTF, screw coupling, M16

- Lab Jack

- Coupler M16

- Coupler M16 with safety valve

* All O-rings are consumable parts

**Overhead stirrer motor is not included