- Home

- Products

- AGI Glassplant

- Filtration

- Filter Dryer

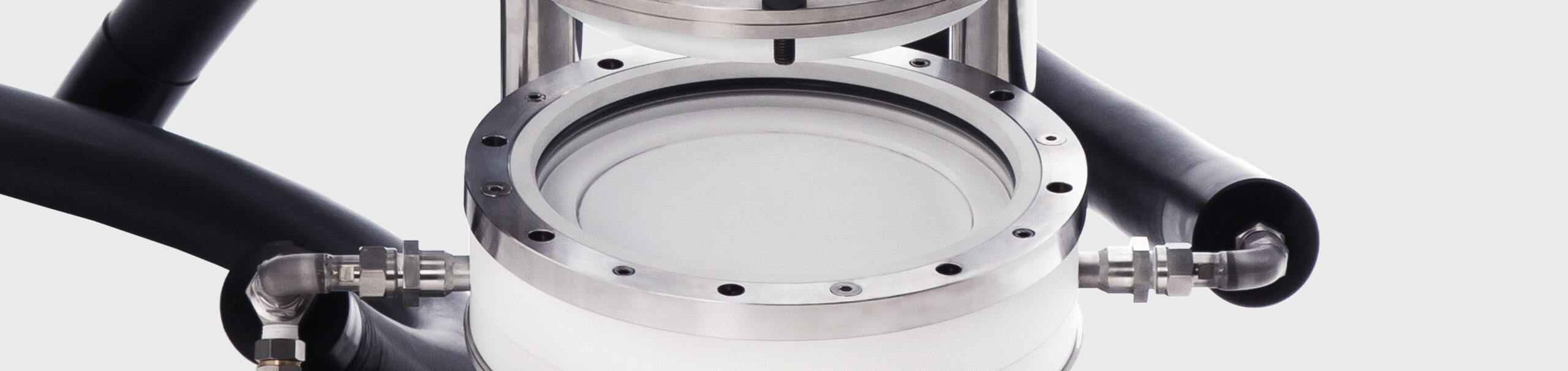

Filter Dryer

AGI Filter Dryer is designed for solid-liquid separation and drying applications. Pressures of up to 2 barG can be applied in the vessel, which helps to accelerate filtration and reduce solvent evaporation at elevated temperatures. The filter dryer integrated in the in filter serves as an extra heat source for accelerated drying of product.

Manual agitation using a flat blade allows gentle slurry mixing, dissolution, cake smoothing and free flowing powder formation. Benchtop Nutsche Filter offers a convenient method for solid-liquid separation and subsequent drying with a high degree of containment and material safety.

- Accelerated filtration and drying

- Minimal product loss and cross-contamination

- All glass design for process visibility

Why should you choose AGI Filter Dryer?

Pressurised filtration up to 2 bar G

Full jacket design for maximised thermal transfer

Accelerated cake drying via filter dryer

Integrated pressure relief and shield for safety

All glass design for continuous process visibility

Removable filter and flush valve for easy cleaning

Wide process temperature range -90 ℃ to +200 ℃

Vessel tilt function for easy product recovery

For a more in-depth explanation of why AGI filtration systems are best for you, click here.

- Pressurised Filtration up to 2 bar G

- Accelerated drying using Filter Dryer

- Hand operated mixing (Motorised - Optional)

- Temperature regulation in jacketed versions

- Temperature Monitoring

- Pressure Monitoring and relief

| Vessel capacity | 1 L, 2 L, 3 L and 5 L |

| Vessel type | Double wall (full jacket) |

| Filtration area | 78.5 cm² (1 L & 2 L) 176.7 cm² (3 L & 5 L) |

| Operating pressure | Full vacuum to +2 barG (+0.2 MPa) |

| Operating jacket pressure | Up to +0.5 barG (+0.05 MPa) |

| Operating temperature | -90 °C to +200 °C |

| ΔT – Thermal shock resistance | 110 °C (double wall) |