Features

Simple and high performance reactor for routine kilo lab and pilot plant production applications

A well-performing reactor lets you achieve high yield and save energy and the time that you spend on your process. Ring Baffle helps you to achieve this.

Ring Baffle is a unique feature available only from AGI. It is a series of ridge-like structures in the thermal wall of the reactor vessel which direct the flow of thermal transfer fluid uniformly around the process vessel.

The uniform flow and local turbulence produced by Ring Baffle enhances the thermal exchange between the wall and process. This effect is not possible in vessels that don’t have Ring Baffle.

This video shows the flow pattern of a black dye in thermal jacket with and without ring baffle. Ring baffle distributes the dye more evenly compared to the vessel without the ring baffle.

- Precise and fast temperature control of the process

- Quick rectification of temperature fluctuations

- Less waiting time for the temperature to reach set-point

- Reduced energy costs and total process time

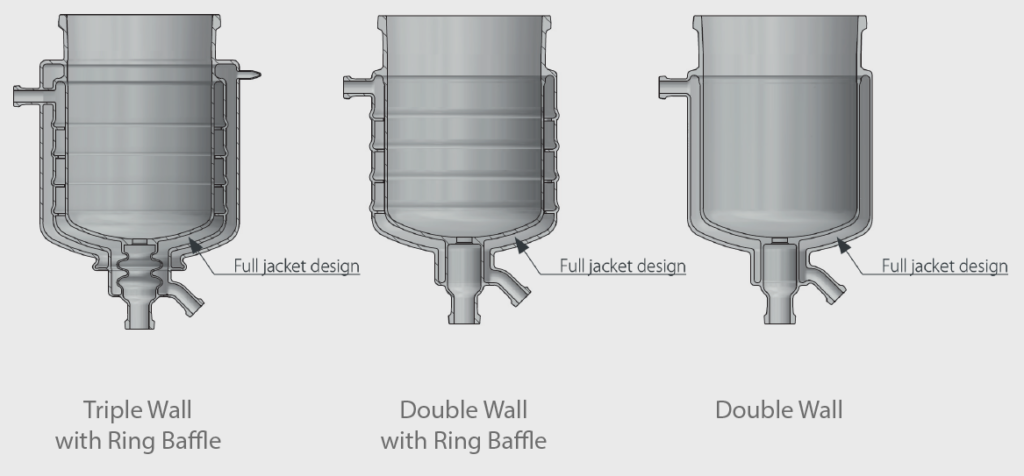

Vessels are a core component of a reaction system. AGI glass vessels are available with double wall (thermal) jacket or triple wall (thermal and vacuum) jacket. Both types are available with or without Ring Baffle. All vessels made by AGI have thermal jackets up to full working volume.

Optimized for excellent heat transfer

The inner vessel wall thickness is optimized using AGI’s propriety resizing method. The benefits of this are :

- Improved thermal exchange

- Reduction of energy expenditure

- Improved process temperature control

Complete jacket cover

Our pilot scale vessels have thermal jackets that cover the process vessel completely. The benefits of this are :

- Efficient use of thermal energy

- Complete immersion of process in set-point temperature

- Better product yield due to uniform and consistent temperature treatment

High thermal shock resistence

Our double and triple wall vessels have the best thermal shock resistance (ΔT) for glass reactors available on the market. This allows for versatility in your process and marks the performance factor of our vessels.

- ΔT for double wall vessels: 110 °C

- ΔT for triple wall vessels: 60 °C

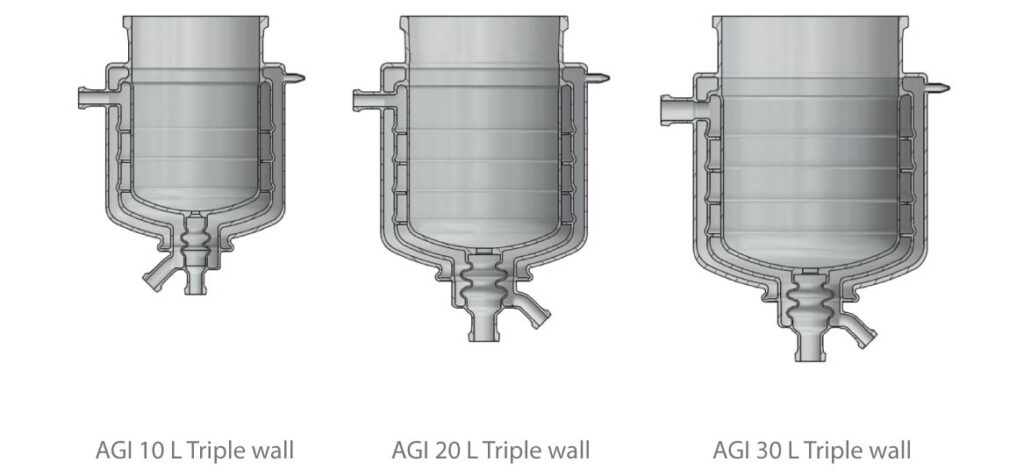

AGI reaction vessels are designed with scale-up in mind. Our triple wall vessel geometry closely resembles the geometry of industrial glass lined reactors.

- Flow dynamics similar to industrial reactors

- Meaningful extrapolation of process parameters for scale-up

| AGI Triple Wall | Competitors | |

|---|---|---|

| Aspect ratio ID (W) : Height (H) |

1:1 ~ 1:1.5 | 1:1 ~ 1:2.5 |

| Bottom Shape | Similar to that of conventional glass lined reactors (10% head plate) |

Round Bottom |

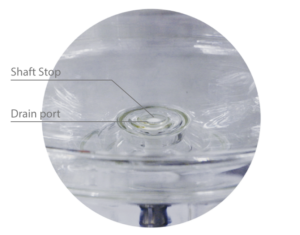

The perfect alignment of a flush valve and its PTFE shaft with the drain port of the reaction vessel provides a continuous surface that leaves negligible dead space. This way, there is minimal stagnation and everything is in movement during agitation.

- 100% effective reaction volume

Cleaning a reactor should be easy to keep the workflow simple and prevent cross-contamination from batch-to-batch. Our reaction vessels are designed with this in mind.

-

Grooveless flat flange

- makes it easy to remove chemical vapour condensates and other residues with a simple wiping action

-

Removable flush valve with run-off design

- prevents formation of any deposits and is removable to enable thorough cleaning

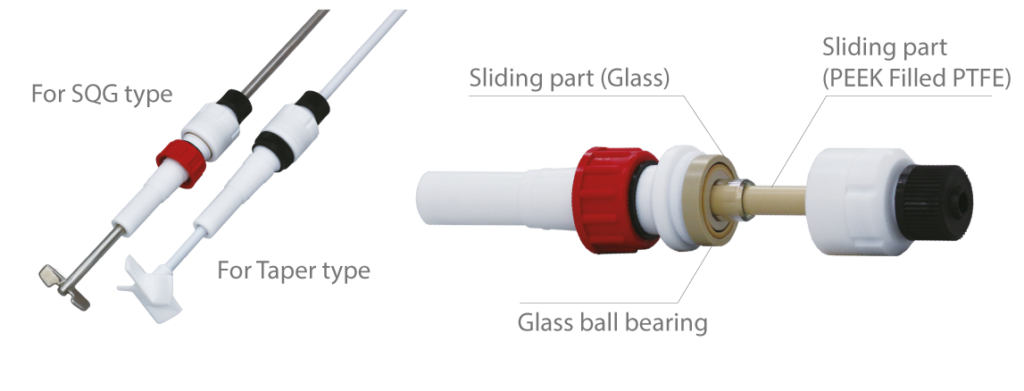

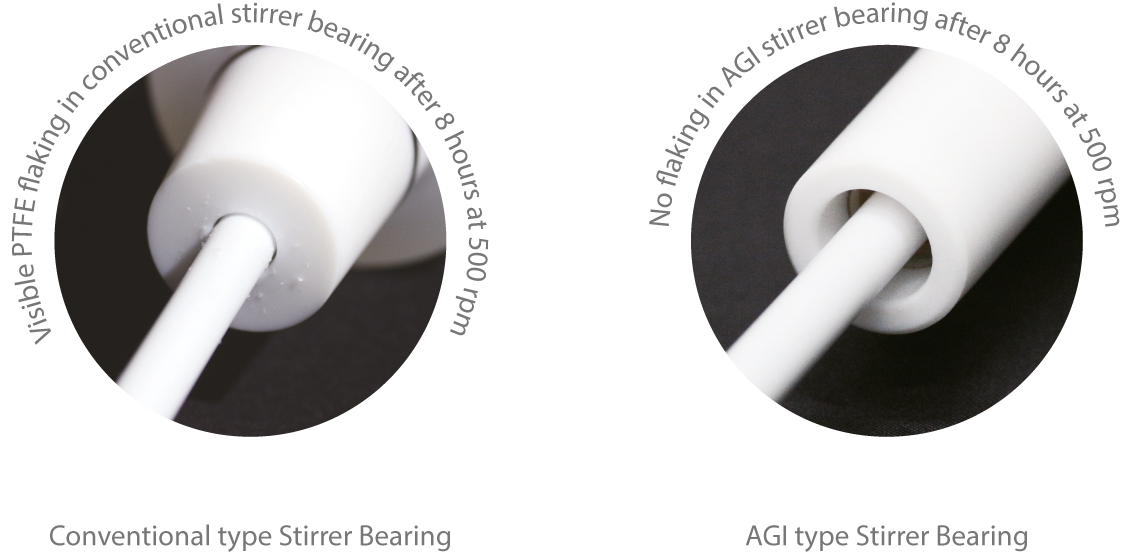

Newly designed AGI stirrer bearings have an extended configuration with glass and PEEK sliding parts. The advantages of AGI’s design are stable and debris-free stirring.

Stable stirring

Debris-free stirring

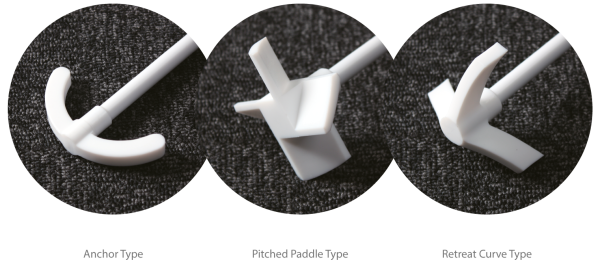

Mass flow pattern is an important factor to consider when you want to achieve a perfect chemical reaction process. We offer three types of impellers with axial or tangential flows. AGI impellers are made of SS rods encapsulated in PTFE for excellent chemical resistance and mechanical strength. If your application requires a special flow, see our advanced impeller options. If you find these are not sufficient, please contact us and we can help you to find a solution that suits your specific process.

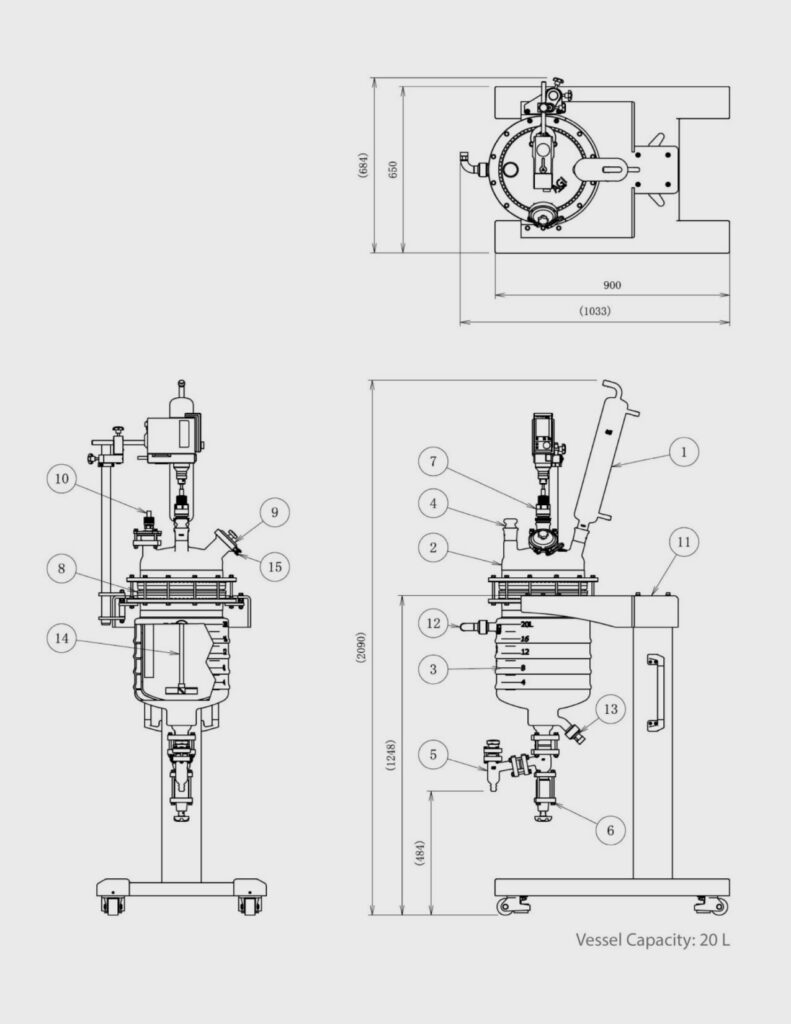

- Condenser

- Vessel Cover, 5 Ports

- Vessel

- Stopper, TS 45/50

- Drain Valve (PVD 25, ф20)

- Flush Valve

- PTFE Stirrer Guide, Glass Ball Bearing, TS 45/50*

- PTFE Gasket with O-ring**

- PTFE Cap for Hand Hole, DN 60

- PT100 Sensor with Holder

- Support Structure

- Metal Adapter for HTF, M30

- Metal Adapter for HTF, M30

- PTFE Stirrer Shaft, Shaft OD: 16 mm

- Quick Release Clamp, DN 60

*Overhead stirrer motor is not included

* *All O-rings are consumable parts