- Home

- Products

- AGI Glassplant

- Quartz

- Quartz Burners

Quartz Burners

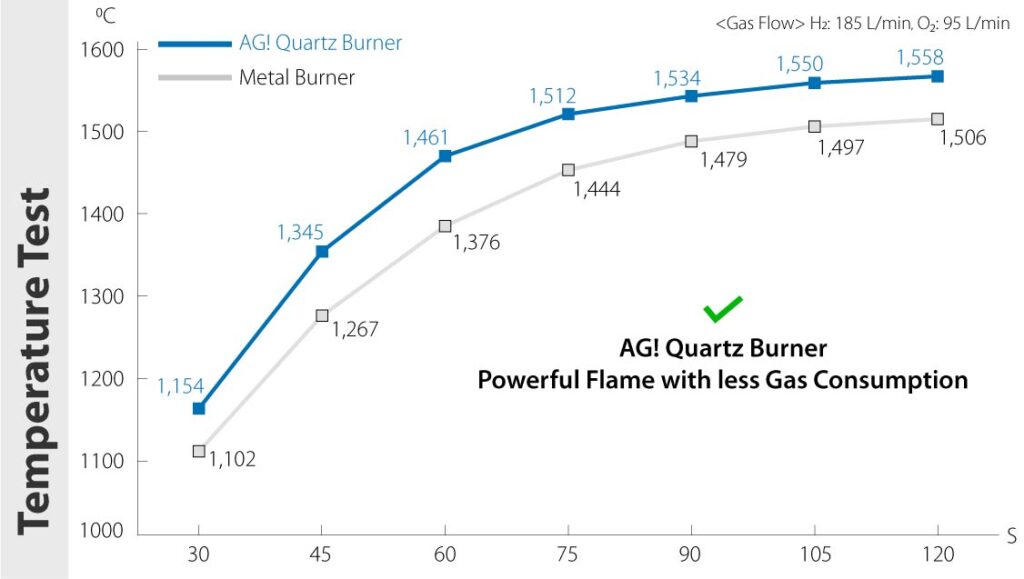

- Fast achievement of reaction set-point temperature.

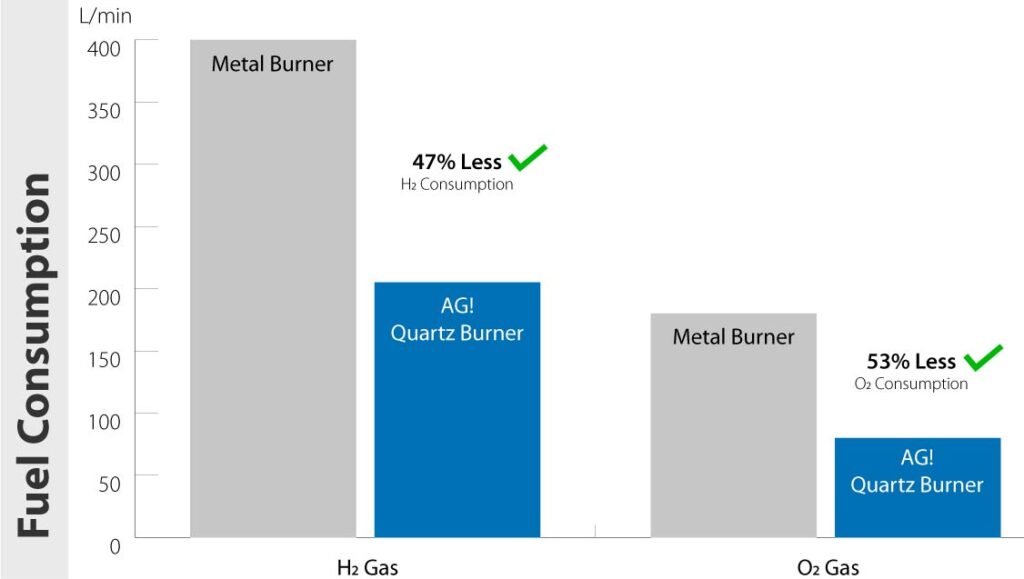

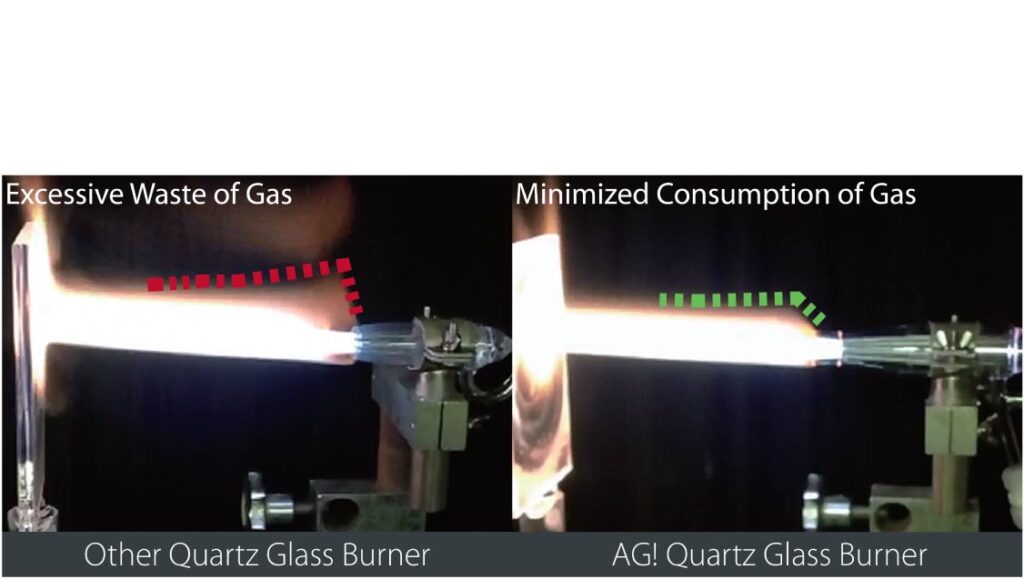

- Reduced energy consumption.

- Interchangeable vessels (300 ml to 5 L).

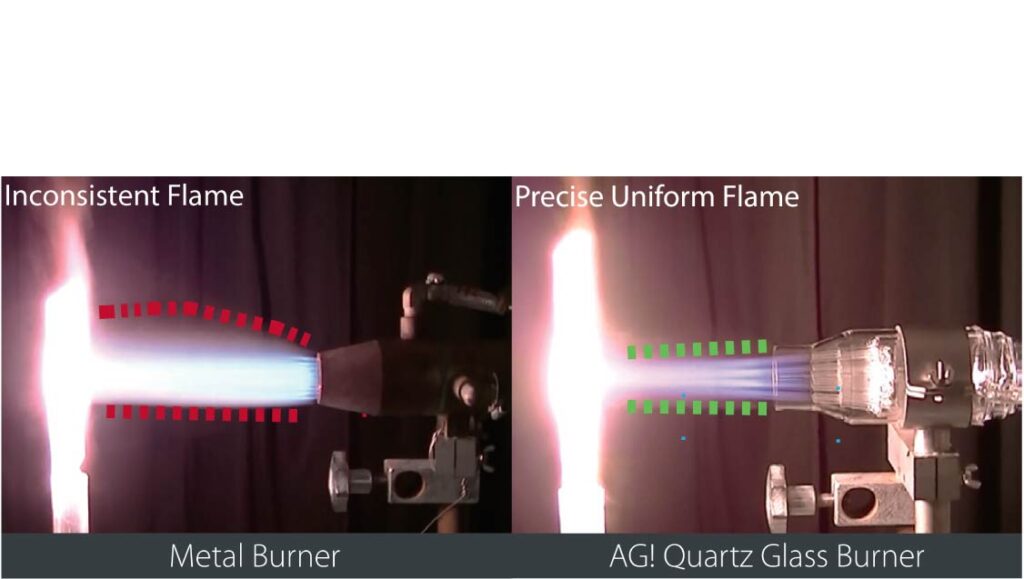

- Stable and powerful flame

- Accurate focal distance

- Less gas consumption

We offer three types of quartz burners for different methods of optical fiber production :

-

AGI Quartz Burner

(for OVD* and VAD**)

-

Multiple Pipe Burner

(for OVD* and VAD**)

-

Multiple Nozzle Burner

(for MCVD***)

*Outside Vapour Deposition, **Vapour Axial Deposition, ***Modified Chemical Vapour Deposition

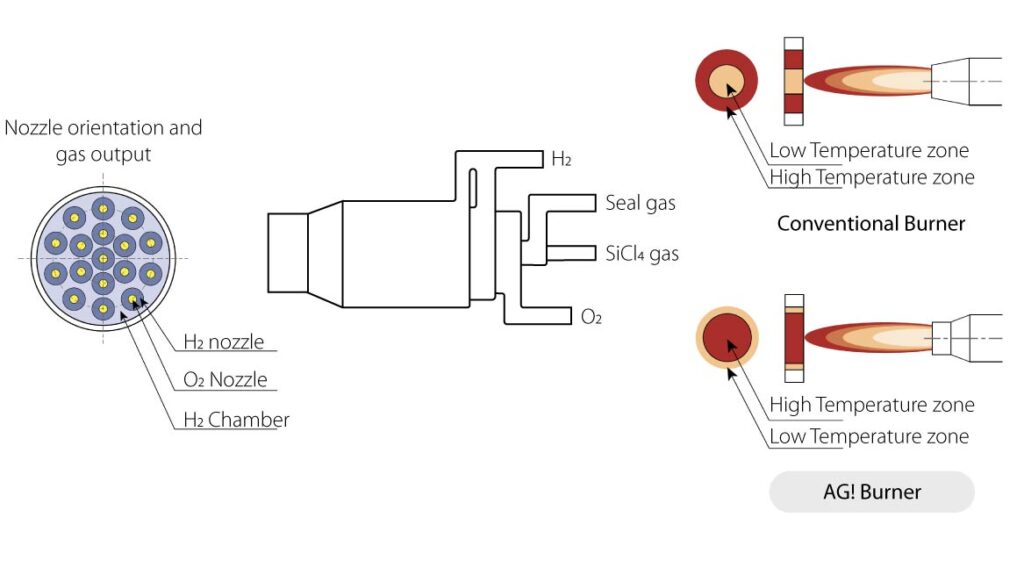

OVD and VAD methods for fibre optic cable manufacturing can benefit from our patented AGI Multiple Nozzle Quartz Burner (Japan Patent No. 3640071) as it provides a strong and stable flame with:

- High accuracy in flame focal length

- High heat and efficiency

- Pure flame with zero contaminants

- AGI proprietary gas mixing provides superior heat, accuracy, and efficiency

- Reduces gas consumption compared to conventional quartz and metal burners

- 100% quartz ensures zero contamination

- Each burner made by AGI is individually inspected and supplied with a 3D inspection report

- O2 nozzle is surrounded by H2 nozzle

- Accurate focal distance

- Max OD: 110 mm

- Custom design to suit focal distance and nozzle orientation is possible

- 3D inspection documentation for accuracy supplied with all burners

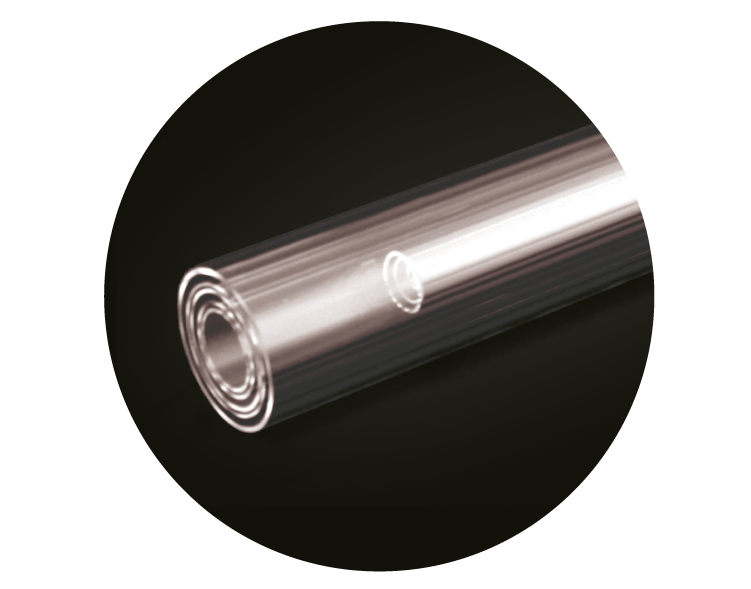

AGI Multiple Pipe Burner is useful for OVD and VAD methods of fiber optic cable manufacturing. Our Multiple Pipe Burner is available in range of different sizes and tolerances, with a maximum outer diameter of 130 mm. Each burner made by AGI is individually inspected and supplied with a 3D inspection report.

| Size | Tube Tolerance (Unit: mm) |

Concentricity Tolerance (Unit: mm) |

| Up to 50 OD | ± 0.05 | ± 0.10 |

| Up to 80 OD | ± 0.10 | ± 0.15 |

| Up to 100 OD | ± 0.15 | ± 0.15 |

| Over 100 OD | ± 0.20 | ± 0.20 |

AGI Multiple Nozzle Burner for MCVD method is made of quartz. The design of this burner produces a high efficiency flame and an accurate focal distance similar to AGI Quartz Burner for OVD and VAD methods. Each burner made by AGI is individually inspected and supplied with a 3D inspection report.