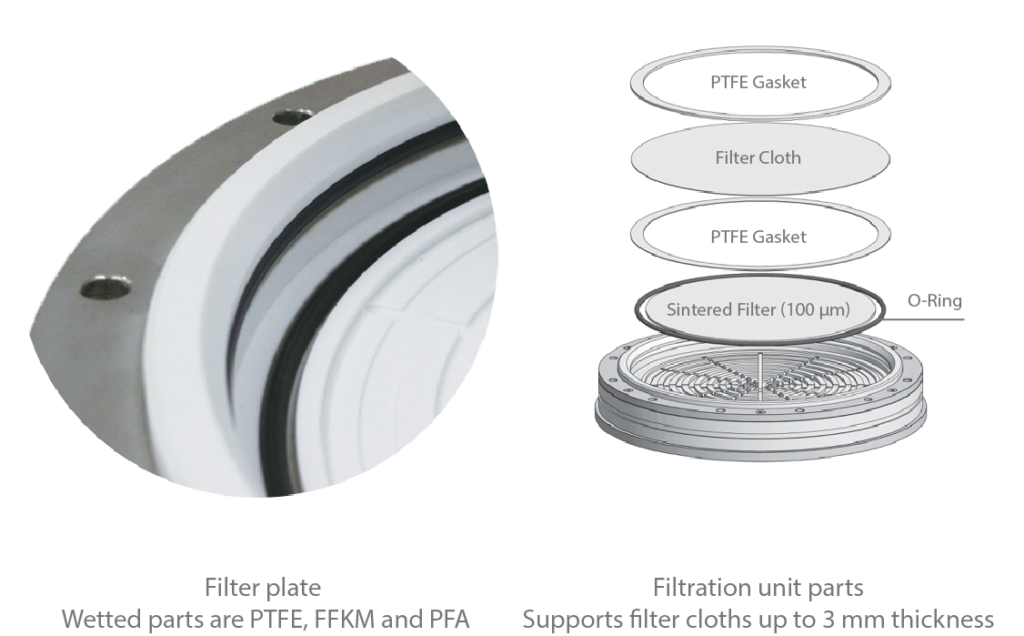

Our filtration part is meticulously designed to prevent any leak or bypass of filtrate. The sintered filter (pore size of about 100 μm) supports the filter membrane. Double PTFE gaskets that sandwich the filter cloth lock everything into place. This setup, along with an O-ring, prevents leaks (including solids, liquids, and gases), and bypasses when the filter is closed. Filter membranes of up to 3 mm thickness can be used.

Features

Explore the features that make the system ideal for crystallisation and filtration applications

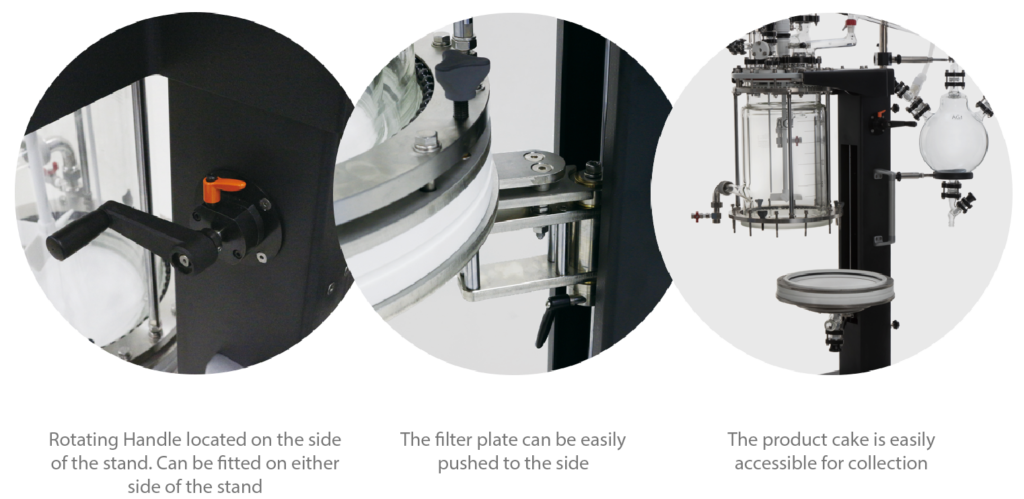

The design of AGI’s filter support structure makes it simple and easy to handle your valuable product, compared to other systems. The filter can be quickly uncoupled, lowered, and moved sideways for filtrate collection. All of this can be done in a smooth, safe, and controlled manner. The lowering of the filter is assisted by a rotating lever mechanism in the support structure.

- Safe and reliable system for product collection

Note: Since the pore size of filter membranes are variable, they are not included in our standard package.

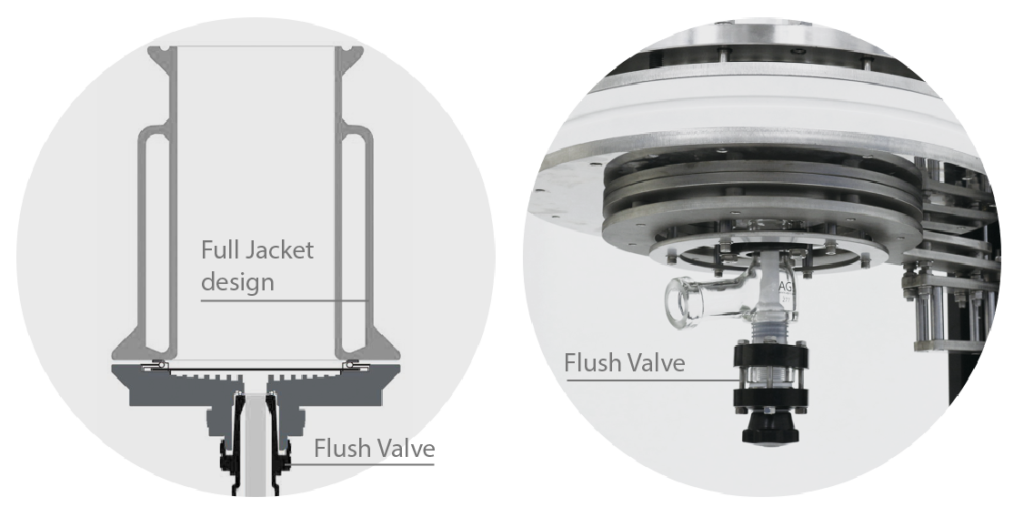

A full jacket design means that the thermal jacket fully covers the process vessel, which offers maximised thermal transfer to the process. The filter and flush valve are designed to provide very minimal dead space.

- High performing vessel

- Filter with low dead volume

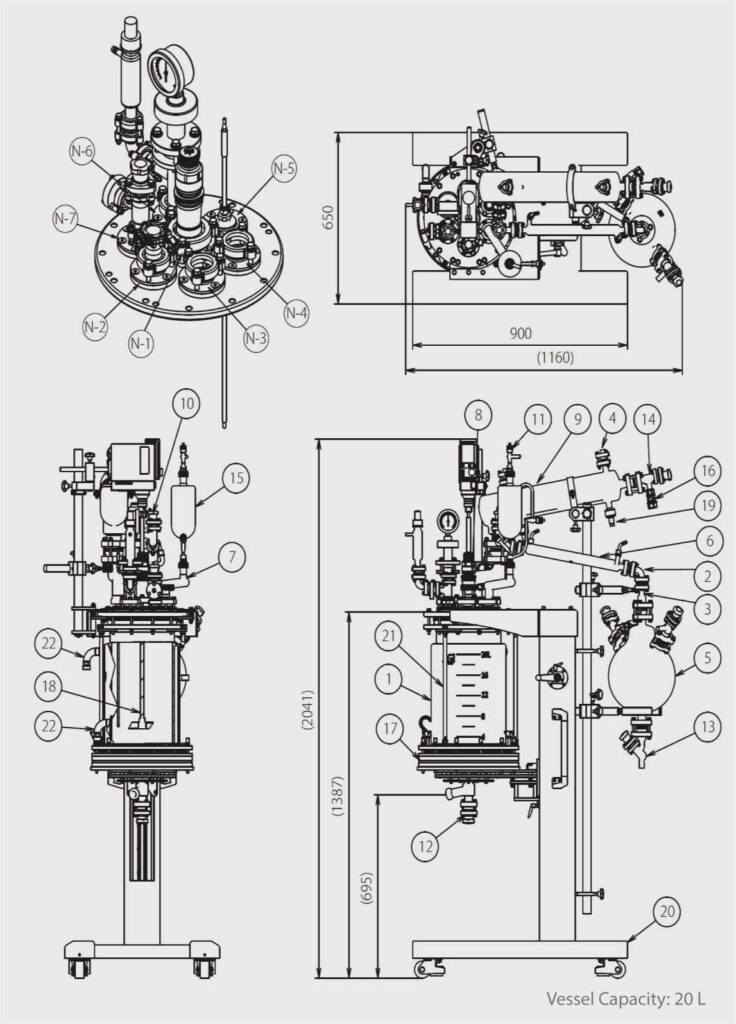

AGI Pilot Plant Filter Reactor is best suited for kilo lab/pilot plant production and process development applications. The PFA-coated SS Lid has adaptable multipurpose 40 A ports with accessories such as purge port, pressure gauge, hand hole, safety valve, condenser, dropping funnel, condensate cooler, condensate receiver, stirrer seal, and temperature sensor. These accessories help to fine tune your crystallisation and create an optimal process.

Note: 10 L models have a vertical condenser. 20 L and 30 L models have diagonal condensers.

For medium-sized filter reactors, thorough cleaning after each use is essential to prevent chemical contamination between batches. It is particularly important to clean the flange and filtration parts.

The flange-grooves where the O-rings sit in standard vessels is prone to collect chemical residues after each process. Our Filter reactor vessel has a flat flange which makes it very easy to clean.

In the filtration part, the gaskets, O-ring and sintered filter are removable. The PTFE filter base has sharp and defined groves to allow easy access for cleaning. The flush valve is removable and has a run-off design where everything drains completely. These design features improve the way you work and clean the reactor, batch after batch.

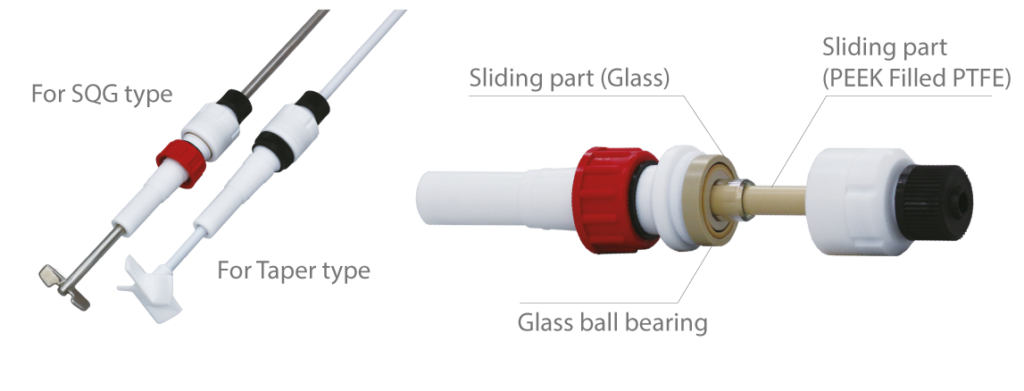

Newly designed AGI stirrer bearings have an extended configuration with glass and PEEK sliding parts.

Stable stirring

Debris-free stirring

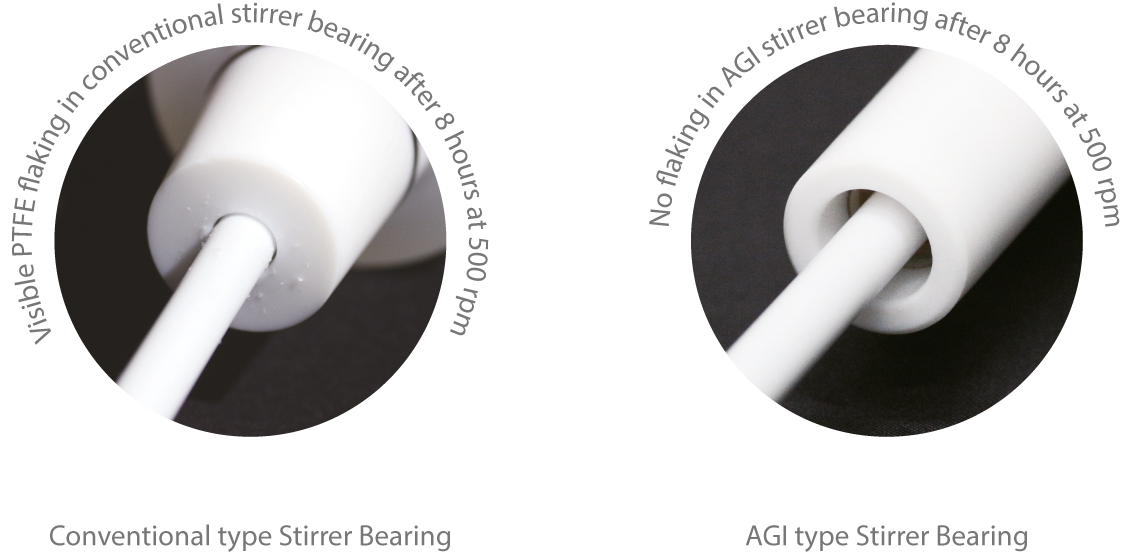

Even with prolonged operation, AGI stirrer bearings are highly resistant to PTFE flaking (from the stirrer shaft) compared with other conventional bearings that are available on the market.

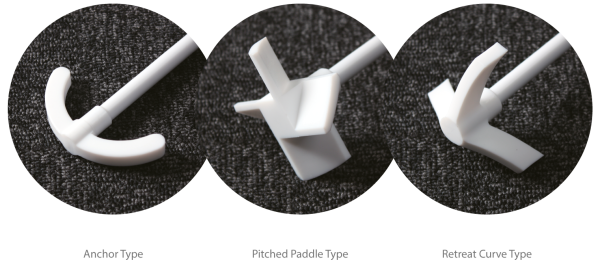

Mass flow pattern is an important factor to consider when you want to achieve a perfect chemical reaction process. We offer three types of impellers with axial or tangential flows. AGI impellers are made of SS rods encapsulated in PTFE for excellent chemical resistance and mechanical strength. If your application requires a special flow, see our advanced impeller options. If you find these are not sufficient, please contact us and we can help you to find a solution that suits your specific process.

- Full Jacket Glass Body,

DN 200 (10 L) / DN 250 (20 L) / DN 300 (30 L) - Bend Adapter (80°)

- Reducer

- Thermometer Pocket

- Receiver

- Product Cooler

- Adapter (SQG 24/40)

- Adapter (40 A, 50 A)

- Condenser with Reflux Divider

- Straight Valve, L Type

- Greaseless Valve (SQG 24/40)

- Flush Valve

- Drain Valve (PVD 25, ф20)

- Vacuum Vent Valve (PVH 25, ф19)

- Dropping Funnel

- Fitting

- Filtration Part, PTFE,

DN 250 (10 L) / DN 300 (20 L) / DN 350 (30 L) - PTFE Stirrer Shaft, Shaft OD: 16 mm

- Adapter for HTF, 15 A

- Support Structure

- Original Flange Set

- Metal Adapter for HTF, Screw Coupling, M30

N-1 Port for PTFE Stirrer Guide

N-2 Hand Hole

N-3 Port for Dropping Funnel

N-4 Port for Condenser

N-5 Pt100 Sensor with Holder

N-6 Compound Pressure Gauge, Safety Valve

N-7 Purge Port (Rc 3/8)

* Ports on Cover Plate: 7 Ports (10 L, 20 L), 8 Ports (30 L)

* 8 Ports include a Spare Port

* All O-rings are consumable parts

* Overhead stirrer motor is not included