- Home

- Products

- AGI Glassplant

- Reaction

- Pressure Reactor

Pressure Reactor

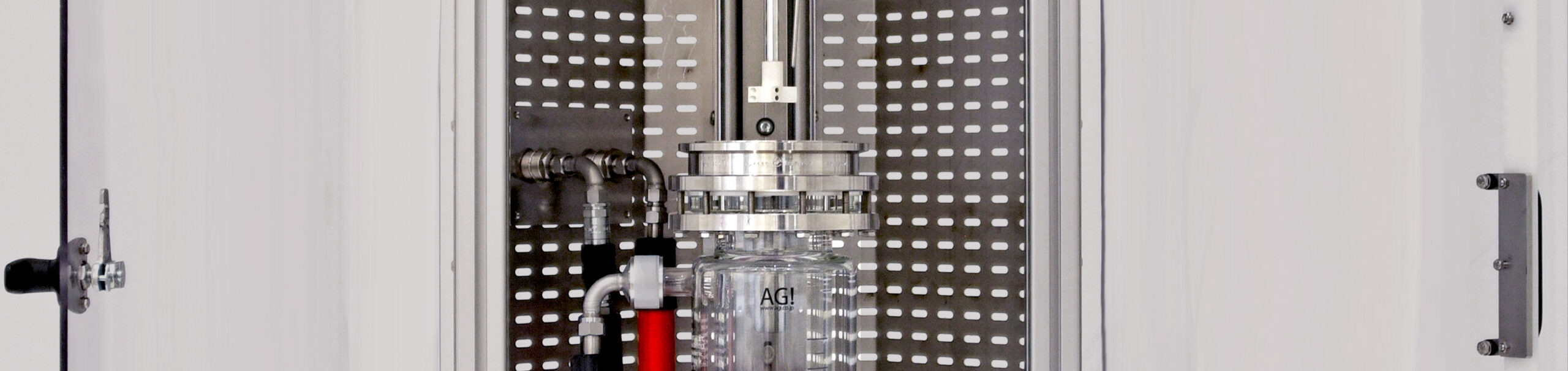

AGI Pressure Reactor can withstand up to 10 barG pressure in an all-glass vessel design. Every glass reactor is pressure tested and has a protective covering for maximal safety. There is a unique removable glass shaft in the flush valve for easy cleaning, and the reactor lid has 8 ports to accommodate various accessories. The magnetic stirrer seal provides protection against pressure leakage and is made of SS316 (Option: Hastelloy®) for excellent corrosion resistance.

The Pressure Reactor is a Gold Label Product.

Why should you choose AGI Pressure Reactor ?

We integrated our knowledge into a system that offers the following advantages :

Up to 10 barG pressure

Flush valve with removable glass shaft

Optimum safety with protective cage and individual pressure testing

All glass body that allows visual monitoring of processes

Wide process temperature range; -90 °C to +200 °C (300 °C as option)

Made of corrosion resistant materials (SS316 or Hastelloy® as option)

For an in-depth explanation of why AGI reaction systems are best for you, click here.

- Reaction under 10 bar G Pressure

- Temperature control via thermal jacket

- Agitation

- Inert gas reactions

- Pressure monitoring and relief

| Vessel capacity | 500 mL, 1 L and 1.5 L |

| Vessel type | Double wall DN80 |

| Operating pressure | Full vacuum to +10 barG (1 MPa) |

| Operating jacket pressure | Up to +0.5 barG (0.05 MPa) |

| Operating temperature | -90 °C to +200 °C |

| ΔT – Thermal shock resistance | 60 °C (double wall) |

AGI has partnered with Mettler Toledo to provide you with a fully automated pressure reactor using an RX-10 reaction control unit. RX-10 provides you with superior control over reactions compared to other automation systems. We offer a complete set up that allows you to capture and report all of your process data in one place using an intuitive touch screen interface.

AGI Pressure reactor with Mettler Toledo RX-10