Thermal process solutions with process warranty – from standardised lab units to tailor-made industrial plants

We deliver individual components, laboratory, and pilot systems as well as turnkey industrial plants for evaporation, distillation and drying. Our process solutions focus on achieving highest product qualities, purities, and yields. With a wide range of individual applications, we offer the exact solution making our customers successful. All is delivered from a single source – all main components and package units are engineered and manufactured in-house.

at VTA headquarters

All key process equipment of our systems – evaporators, cold traps, columns, heat exchangers, vessels – are manufactured either by VTA in Niederwinkling (Germany) or within the STREICHER company group. In four modern manufacturing areas highly qualified workers manufacture welding structures up to 100 tons.

Your Benefits

- Highest quality standards

- Full production control

- Quick reactions to customer requests through local closeness of process development, design and manufacturing

- Complete installation with subsequent individual testing and 3rd party acceptance

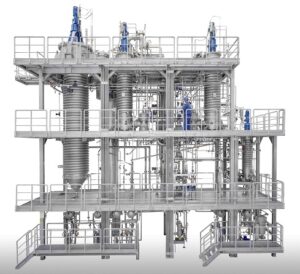

Skid-mounted plants and complete project management

All key process equipment of our systems – evaporators, cold traps, columns, heat exchangers, vessels – are manufactured either by VTA in Niederwinkling (Germany) or within the STREICHER company group. In four modern manufacturing areas highly qualified workers manufacture welding structures up to 100 tons.

Your Benefits

- Highest quality standards

- Full production control

- Quick reactions to customer requests through local closeness of process development, design and manufacturing

- Complete installation with subsequent individual testing and 3rd party acceptance

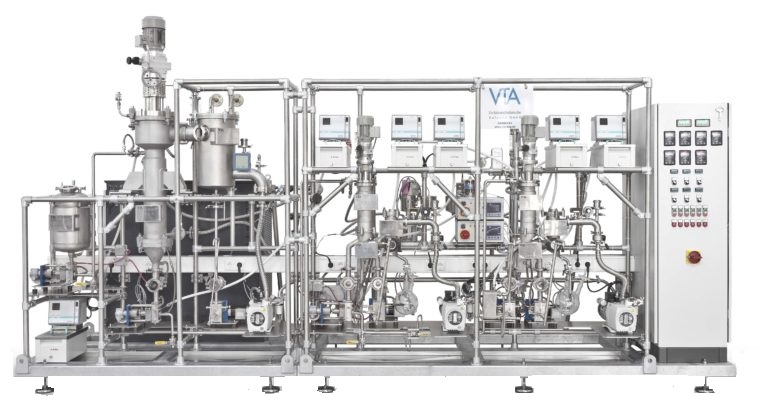

With laboratory units, reliable conclusions about the feasibility of a separation process can be made by only using small product amounts. The set-up and design of the lab units VTA offers to customers is based on the experience gained in VTA’s own test center for years.

Lab units are used for :

- Verifying the feasibility of a separation task.

- Doing first process development steps.

- Producing small sample amounts of final product.

- Optimizing existing processes.

Main target is to generate scalable data and results during the pilot tests (with small sample quantities) to enable a later scale up to industrial systems. Furthermore these pilot systems can be used for distillation or drying of small product quantities.Experience, gained by experiments with a variety of products in VTA’s own pilot plants, has influenced the design and continuously improves the quality and performance of the systems.

Pilot plants are used for :

- Generating the scalable data for industrial systems.

- Producing certain sample quantities.

- Optimization of existing processes.

VTA provides industrial scale systems as package units. Package units are skid mounted, pre- assembled systems for wiped film and short path distillation, rectification and thin film drying.

Evaporator Size up to 80m2.

| Features of Laboratory Units | |

|---|---|

| Typical feed rate | 20 g/h up to approx. 12 kg/h |

| Material main components | Borosilicate glass |

| Max. heating temperature | 350o C |

| Achievable pressure in wiped film evaporator | < 0.1 mbar |

| Evaporator size | 0.01 up to 0.40 m2 |

| Achievable pressure in short path evaporator | < 0.001 mbar |

| Features of Pilot Plants | |

|---|---|

| Typical feed rate | 5 kg/h up to approx. 50 kg/h |

| Material main components | Stainless steel or special material |

| Max. heating temperature | 350 oC ( Thermal oil) For high heating temperatures: Inductive and electrical heating possible |

| Evaporator size | 0.06 up to 0.50 m2 |

| Achievable pressure in wipedfilm evaporator | 0.1 mbar |

| Achievable pressure in short path evaporator | < 0.001 mbar |