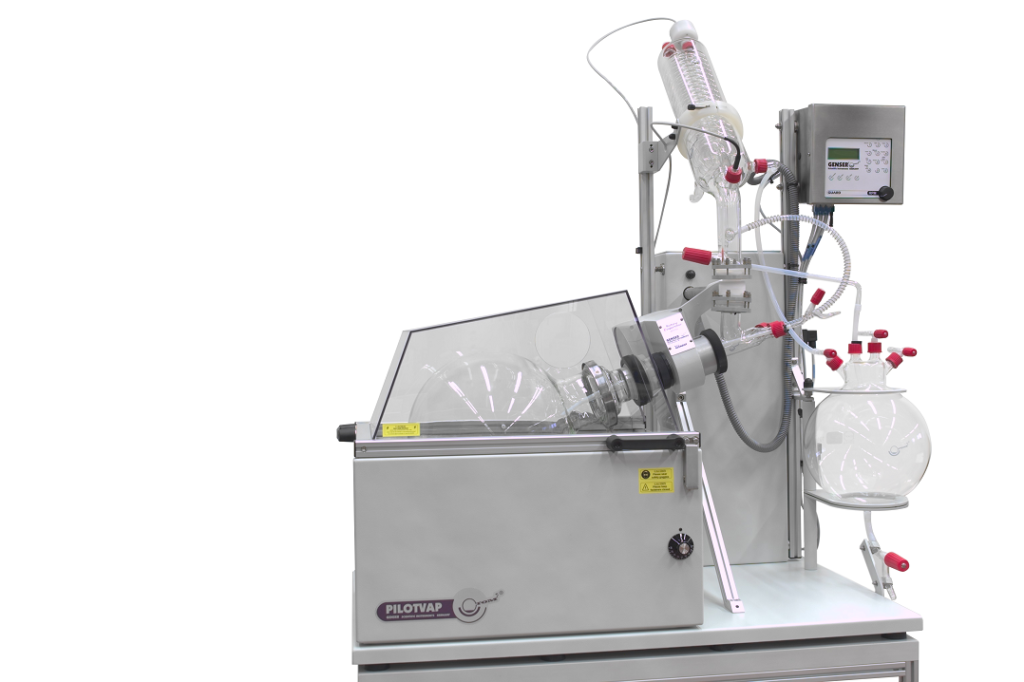

Rotary Evaporator PILOTVAP®

The PILOTVAP® is a patented pendulum system rotary evaporator.

PILOTVAP® Applications :

- Excellent suitable for recovery of solvents.

- Problem-free distillation of high boiling solvents.

- Distillation of large amounts of solvent.

- Concentration of extracts.

- Drying of powders.

- Concentration of fractions coming from HPLC.

- We would be glad to develop with you customer specified solutions.

Hint: All PILOTVAP®-Systems can be modified to the fully automated rotary evaporator POWERVAP®.

Technical Details of the PILOTVAP® :

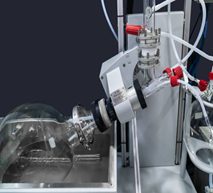

The floating rotating flask reduces mechanical stresses, to achieve constant tightness and a powerful distillation result, even under permanent operation (see pendulum system)

The floating rotating flask reduces mechanical stresses, to achieve constant tightness and a powerful distillation result, even under permanent operation (see pendulum system)- Hydraulic damping system for the rotating flask with drive system (patented), to increase the performance, when drying powders.

- Surface treated glass flanges for maximal vacuum stability.

High performance sealing system

High performance sealing system

– PTFE / glass or Special High Chemical Resistant sealing system (HCR seals) to sustain corrosive solvents like: TFA, DMF, DMSO, etc.

– Service life approx. 20,000 hours of operation

– Final vacuum better than 0.1 hPa (when empty)

– 3 years warranty- Sealing system STACONSEAL, patented (option)

– Final vacuum better than 0.01 hPa (when empty). - By means of the novel sealing system, a very good solvent recovery rate will be achieved.

- Vapor temperature alarm, to automatically shut off the water bath.

- Implosion protection hood for the rotating flask, made of transparent polycarbonate.

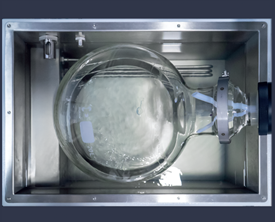

- The pendulum system makes the rotating flask float in the water bath, to guarantee highest performance, easy handling and maximal reliability.

- Manual or automatic vacuum control.

- Control of the aerating valve (air- or nitrogen inlet).

- Vapor temperature control.

- Speed control with slow acceleration mode

- Control of the water bath temperature.

- Speed control with slow acceleration mode.

- Control of the water bath temperature (option).

- Vapor temperature control (option).

Technical features of the process controller GUARD :

- Manual vacuum control with ACCEPT function to easily select the SET value.

- Automated vacuum control.

- Emergency SHUT OFF and aeration at overpressure (alarm).

- Temperature control of heating bath.

- Vapor temperature control.

- Pulse aerating.

- Speed control with slow accelerating mode.

- Automated speed control (patented/option).

- Torr/hPa (mbar) selector.

- RS232-interface.

- USB-interface (option).

- Output for vacuum pump (solid state).

- Coolant temperature indicator (option).

- Capacitive keyboard – chemically resistant.

- Control of foam by pulse dosing (patented/option).

- STACONSEAL sealing monitoring device for vacuum values better than 0.1 hPa – excellent for high boiling solvents and best product qualities (patented/option).

- Customer specified solutions (option).