Process solution for special requirements

The working principle of horizontal thin film evaporators is similar to vertical thin film evaporators. However the horizontal design allows highest flexibility in terms of residence time, evaporation rates and turn-down ratios. The recovery of large solvent amounts from viscous products, processing of inhomogeneous products or performing continuous reactions are applications for this technology. For pharmaceutical or food applications horizontal thin film evaporation plants can be designed for full GMP and in hygienic design.

- Capacity: 0,1 kg/h up to several t/h

- Operating pressure: full vacuum to overpressure

- Evaporation ratio: max. 99.5%

- Turn down ratio: not limited

- Visosity: max. 75.000 mPas at operating temperature

- Residence time: adjustable

- Continuous reactions: possible

Processing of thermal sensitive, viscous or foaming products such as

- Lecithin drying

- Concentration of natural extracts

- Peptide solutions

- Solvent recovery from polymer side streams

- Active pharmaceutical ingredients

- Acrylic polymers

- Installation: less height required

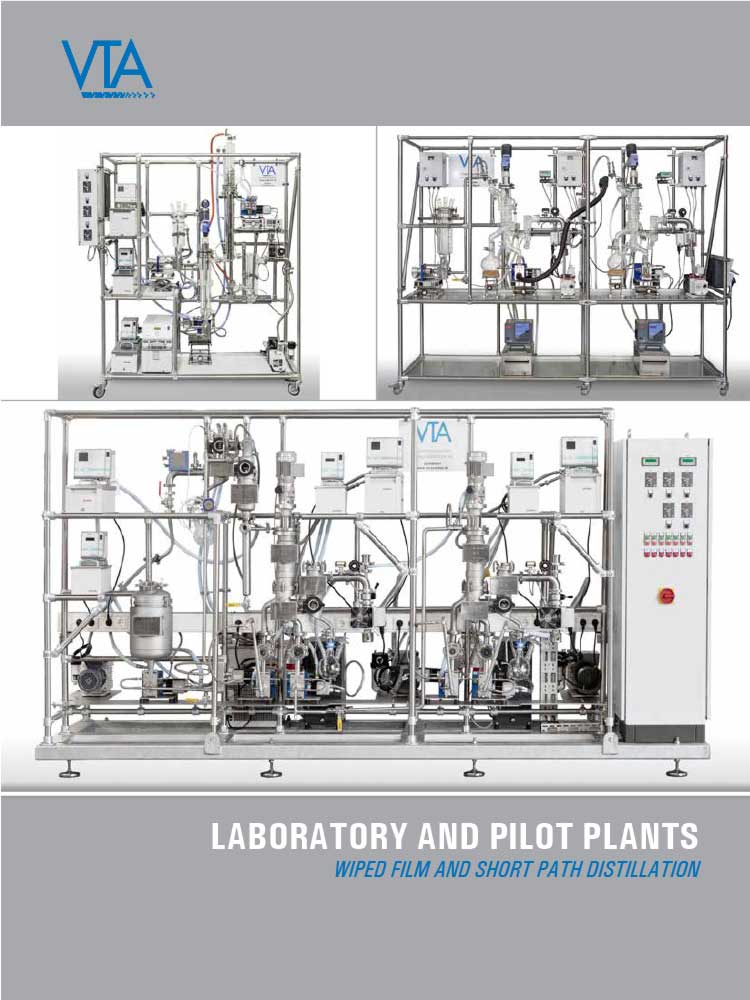

- Available scales: Laboratory, Pilot and Industrial

- Material of construction: glass, stainless steel, special alloys

- GMP and hygienic version: free overhung rotor design with signe rotary transmission

- Shell and rotor: straight or tapered

Are you interested in VTA Horizontal Thin Film evaporators? Testing at VTA test center?

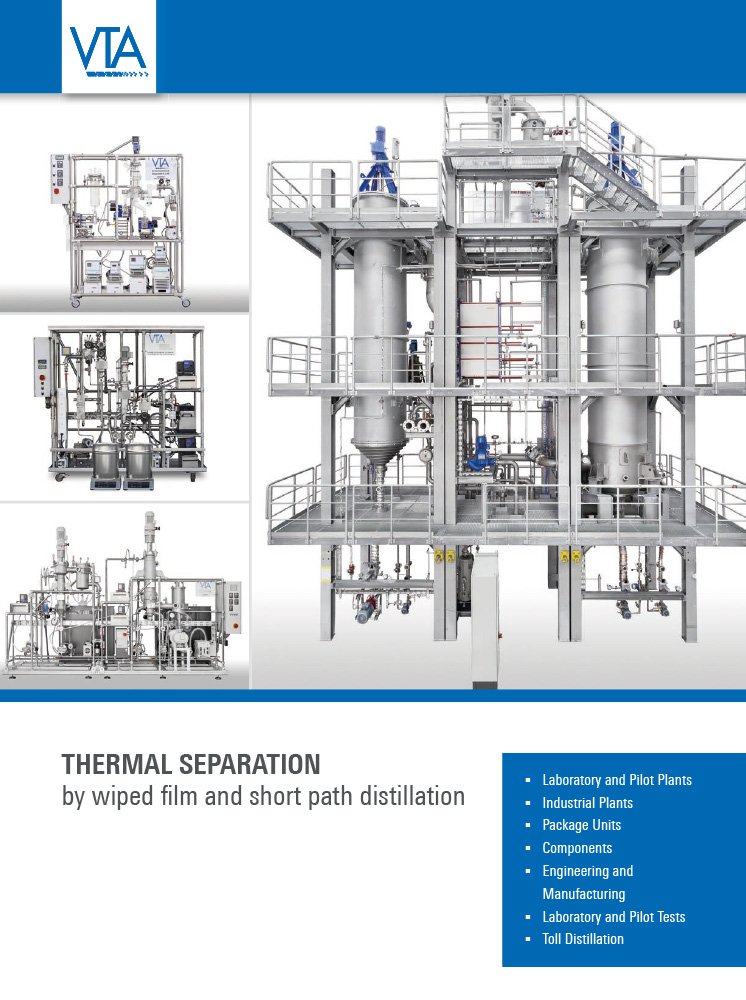

VTA − plant design at its best

VTA delivers package units in laboratory, pilot and industrial scale. Package units are skid mounted, pre-assembled systems for wiped film and short path distillation, rectification and thin film drying. All core components, like evaporators, condensers, vessels and piping, are manufactured in modern manufacturing facilities by highly qualified workers either by VTA or within the STREICHER group. All engineering services are performed entirely inhouse at VTA. By minimizing the interfaces, a smooth project execution is ensured.